Air compressors are one of the important large-scale fixed power equipment in coal mines. They are widely used underground and on the ground. They are mainly used for pneumatic picks, pneumatic drills, and rock drills in the mining face. The air storage tank is the supporting equipment of the air compressor. It is installed outdoors. The air enters the compressor and is pressurized and then sent to the air storage tank. Then the air storage tank pipeline is supplied to each gas location. The air storage tank is in the air compression system. The main function of the air supply is to ensure the stability of the gas supply. The compressed air deposits water in the air storage tank, adjusts the air pressure fluctuation of the pneumatic equipment due to the unbalanced air consumption, increases the pressure stability of the air equipment, or reserves a part of the compressed air. When the air compressor fails, the user can use it. This part of the compressed air is used for emergency treatment of pneumatic equipment or pneumatic control systems.

Inspection requirements for gas storage tanks

Usually as a simple pressure vessel, the air compressor tank has always been regarded as a relatively reliable special equipment, but it also has certain risks. If there are problems in design, manufacturing quality, installation standards, operation, and management, Failure to meet the requirements of the regulations will bury hidden dangers, and serious accidents may occur during use, causing casualties and equipment damage.

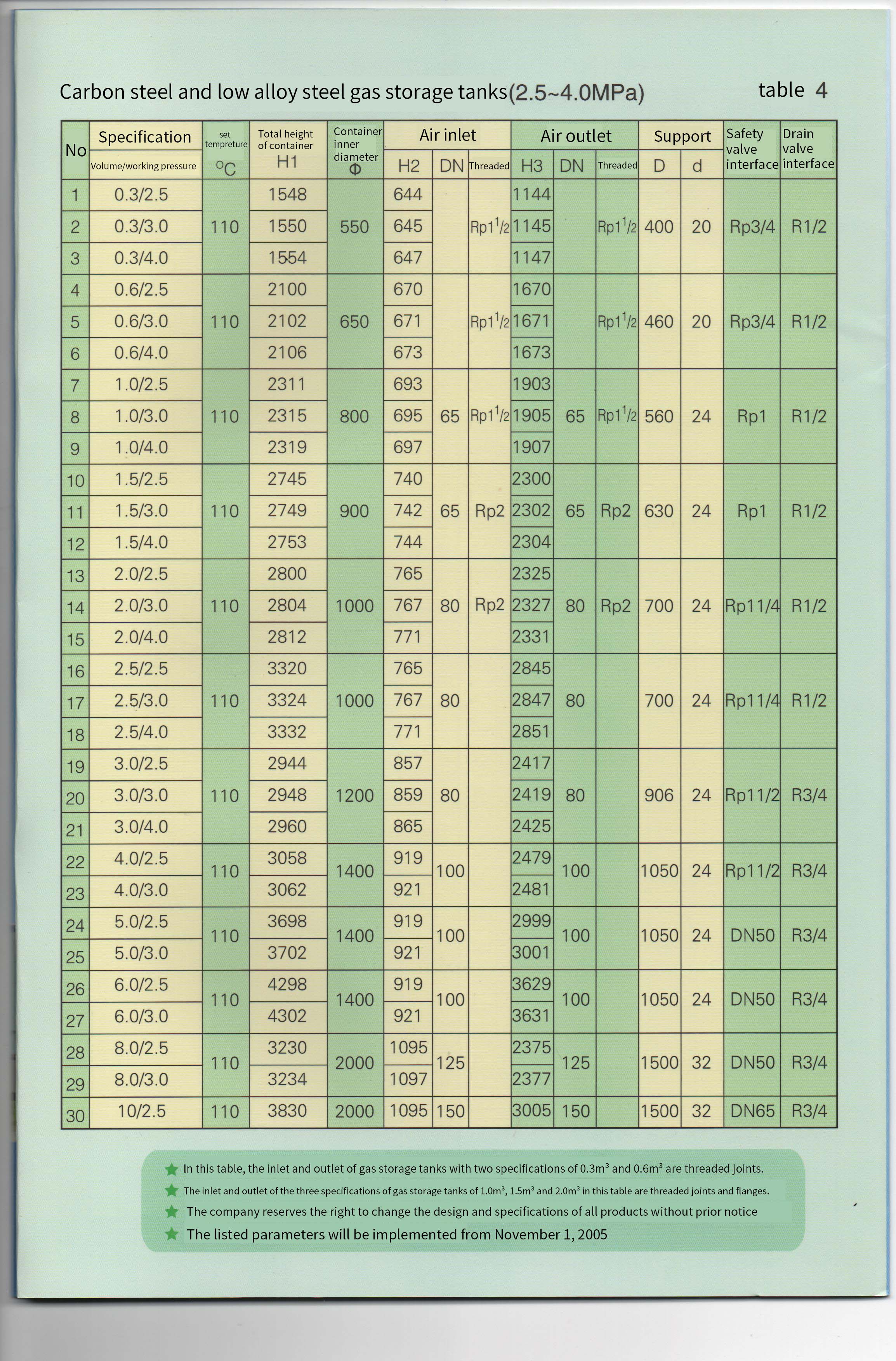

The gas storage tank needs to be reported for installation before installation. After installation, the pressure vessel use certificate and regular inspection shall be carried out in accordance with the requirements of special equipment. After the inspection is qualified and the inspection report is obtained, it can be put into use. Regular inspections should be carried out according to the pressure level and service life of the gas storage tanks. Gas storage tanks that have not passed the regular inspection shall not be used. The volume and pressure of the air storage tank should meet the design standards and cannot be configured casually. One air compressor is equipped with one air storage tank. The air storage tank of the ground air compressor station should be protected from direct sunlight, the air storage tank has inspection holes, and the grease in the tank should be cleaned regularly.

Gas tank accessories and protection device requirements

1. Gas storage tank accessories

Gas tank pressure gauge

The main function of the gas tank pressure gauge is to indicate the pressure of the medium in the tank. The pressure gauge should be checked once a year and has an inspection certificate. If the pressure gauge is found to be damaged during use, it should be replaced in time to ensure that the pressure gauge is accurate.

2. Gas storage tank protection device

1) The gas storage tank is equipped with an over-temperature protection device. The temperature in the gas storage tank should be kept below 120°C during operation, and the power supply can be automatically cut off and an alarm will be issued when the temperature is over-temperature.

2) Install a pressure relief valve on the outlet pipe of the air storage tank, the diameter of which should not be smaller than the diameter of the air pipe, and the relief pressure should be 1.25 to 1.4 times the working pressure of the air compressor.

3) Since the compressed air has a relatively high temperature, it will gradually cool down after passing through the air storage tank, and the moisture in the air will also condense. Therefore, the drain valve at the bottom of the air storage tank must be opened regularly to drain this part of the moisture. Otherwise, It will not only affect the quality of compressed air but also rust out the air tank, so the air tank is equipped with a drainage device.

The drainage device is equipped with manual switch and solenoid valve switch. Under normal circumstances, there is no need for manual timing drainage; if the solenoid valve fails, the manual switch can also be manually opened for drainage, which makes the entire air compressor gas tank of high reliability, high efficiency, High reliability and long service life.